Thread Rolling Dies Brochure

Visit our Product Brochures to view information on Thread Rolling Dies.

Reed and Hi-Life Tools manufacture flat thread rolling dies under the strictest quality standards and most precise dimensional control - to ensure perfectly matched threads of the correct lead angle on a pair of mating dies.

Such rigid standards facilitate easy setup, uniformly accurate threads, improved manufacturing yields, reduced machine downtime and longer die life.

PTG's regional service centers have hundreds of types of flat dies in stock for fast delivery, including dies for machine and cap screws, tapping screws type A, AB, type F screws, type B screws, and HiLo forms. Flat dies are also available for rolling all special threads and forms.

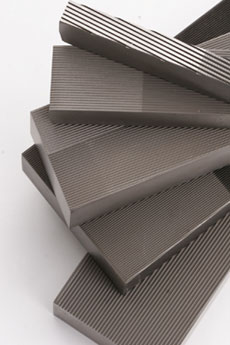

Popular Flat Thread Rolling Die Profiles

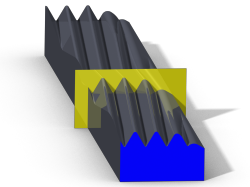

Typical Roll-On/Roll-Off on Flat Thread Rolling Dies

Classic Profile Thread Rolling Dies

For rolling exotic materials like titanium alloys for aerospace and other high-grade applications, Hi-Life offers the Classic Profile thread rolling dies. By incorporating a "full form radial" start as opposed to a ground chamfered start, less severe indentations are made on the screw blank - allowing the blank to begin rolling in the optimum upright position.

Flaw Free Form (F3®) Technology

Reed's Patented Flaw Free Form (F3®) dies were developed to help roll the best quality fasteners without modifying any of the processes (e.g. blank preparation and machine operation). In controlling manufacturing variables to yield lap-free threaded fasteners, F3® technology:

- Helps maintain normal production rates and machine speeds - even when rolling critical fasteners with harder materials

- Enhances control of grain flow, whereby F3® dies begin forming the thread crest almost immediately; no other thread rolling die in the world has this capability

- Improves physical characteristics of the fasteners due to the controlled nature of material displacement. Specifically, the smooth surface finish and compressive residual surface stresses introduced by rolling make rolled fasteners stronger in fatigue, shear and tensile strength

Flaw Free Form Brochure

Visit our Product Brochures to view information on Flaw Free Form Technology.

Radiused Root Runout (RRO)

Since flat dies with sharp corners on the runout threads generate stress concentration areas that result in fatigue cracks on the thread rolled screw, PTG brands offer controlled radiused root runout (RRO) as a standard feature on all dies. With RRO, the smooth radius in the thread root continues to the point at which the thread blends in the screw shank. This radius distributes stresses evenly - increasing fatigue resistance in an area of the screw where failure is most likely to occur.